Everything You Need to Know About 14 Drywall A Comprehensive Guide

Drywall, also known as sheetrock or plasterboard, is a widely used material in the construction industry for creating walls and partitions. It plays a crucial role in building construction, providing a smooth and durable surface for interior walls.

Unlike traditional plaster, which requires time-consuming application and drying processes, drywall offers a more efficient solution. It consists of a layer of gypsum sandwiched between two layers of paper, making it easy to install and repair.

Drywall is lightweight, making it easier to handle and transport, while still maintaining its strength and durability. It is commonly used in residential and commercial buildings, providing a cost-effective and efficient way to create interior walls and partitions.

Whether you’re planning a renovation or starting a new construction project, understanding the benefits and considerations of drywall can help you make informed decisions. In this comprehensive guide, we’ll explore the different types of drywall, installation techniques, and tips for maintenance and repair.

What is 1/4 Drywall?

1/4 drywall, also known as thin drywall or gypsum board, is a type of construction material commonly used in building walls, partitions, and ceilings. It is a lightweight and versatile material that is made from a core of gypsum plaster sandwiched between layers of paper.

1/4 drywall is thinner than standard drywall, which is typically 1/2 inch thick. Its thinner profile makes it easier to handle and install, especially in tight spaces or areas where weight is a concern. This type of drywall is commonly used for repair work, remodeling projects, or in applications where a thinner wall or partition is desired.

Despite its thinner profile, 1/4 drywall still provides adequate strength and durability. It can be used in both residential and commercial construction projects, and it meets the same building code requirements as standard drywall.

When installing 1/4 drywall, it is important to use the appropriate fasteners and techniques to ensure a secure and stable installation. Due to its thinness, 1/4 drywall may be more prone to sagging or cracking if not properly supported. It is also important to properly finish and seal the joints and edges of the drywall to ensure a smooth and seamless appearance.

In summary, 1/4 drywall is a thinner version of standard drywall that is commonly used in construction projects where weight or space is a concern. It is a versatile and durable material that can be used for walls, partitions, and ceilings. When installed correctly, it provides a smooth and seamless finish for any building or remodeling project.

Benefits of Using 1/4 Drywall

1. Lightweight: 1/4 drywall is a lightweight building material, making it easier to handle and install compared to thicker drywall options. Its light weight also reduces the strain on the structure and framing of the building.

2. Versatility: 1/4 drywall, also known as gypsum board or sheetrock, can be used for various construction purposes. It is commonly used for interior walls, ceilings, and partitions in residential and commercial buildings.

3. Space-saving: Due to its thin profile, 1/4 drywall helps save space in rooms where every inch counts. It is especially beneficial in small spaces where thicker drywall may make the area feel cramped.

4. Easy to cut and shape: 1/4 drywall can be easily cut and shaped to fit any space, making it a versatile material for construction projects. It can be scored and snapped or cut with a utility knife, making installation quick and efficient.

5. Cost-effective: 1/4 drywall is typically less expensive than thicker drywall options, making it a cost-effective choice for construction projects. It provides a durable and functional solution without breaking the budget.

6. Fire-resistant: Like other types of drywall, 1/4 drywall is made with gypsum, which is a naturally fire-resistant material. It helps to slow down the spread of fire, providing additional safety in buildings.

7. Soundproofing: 1/4 drywall can help reduce noise transmission between rooms. Its thickness and composition help to absorb sound and improve the acoustic properties of a space.

8. Easy to finish: 1/4 drywall can be easily finished with plaster or joint compound to create a smooth and seamless surface. It can then be painted or textured to achieve the desired aesthetic.

9. Environmentally friendly: 1/4 drywall is made from natural gypsum, which is a non-toxic and recyclable material. Using 1/4 drywall in construction projects can contribute to sustainable building practices.

Overall, 1/4 drywall offers numerous benefits in terms of its lightweight nature, versatility, space-saving properties, ease of installation, cost-effectiveness, fire resistance, soundproofing capabilities, ease of finishing, and environmental friendliness. It is an excellent choice for various construction projects that require a thin and reliable building material.

Common Applications

Drywall, also known as sheetrock or plasterboard, is a widely used material in the construction industry. It is primarily used for interior walls and ceilings in both residential and commercial buildings. Drywall is made of gypsum, a mineral that is mined and then processed into a powder. The powder is mixed with water to form a paste, which is then spread onto a layer of paper and dried to create a solid panel.

One of the most common applications of drywall is as a partition material. It is used to create separate rooms and spaces within a building. Drywall partitions are lightweight, easy to install, and provide good sound insulation. They are commonly used in offices, schools, hospitals, and other commercial buildings.

Drywall is also used for finishing interior walls. Once the drywall panels are installed, they are typically covered with a layer of joint compound and then sanded smooth. This creates a seamless surface that can be painted or wallpapered. Drywall is a popular choice for finishing walls because it is cost-effective and provides a smooth and durable surface.

In addition to partitions and finishing walls, drywall is also used for ceilings. Drywall ceilings are commonly seen in residential homes, office buildings, and other commercial spaces. They provide a clean and finished look to a room and can be easily painted or decorated.

Another common application of drywall is in the construction of fire-rated walls. Drywall can be manufactured with fire-resistant properties, making it a suitable material for creating fire barriers and protecting against the spread of flames. Fire-rated drywall is used in areas where fire safety is a concern, such as stairwells, mechanical rooms, and corridors.

Overall, drywall is a versatile and widely used material in the construction industry. Its ease of installation, cost-effectiveness, and durability make it a popular choice for a variety of applications, including partitions, finishing walls, ceilings, and fire-rated walls.

Installation

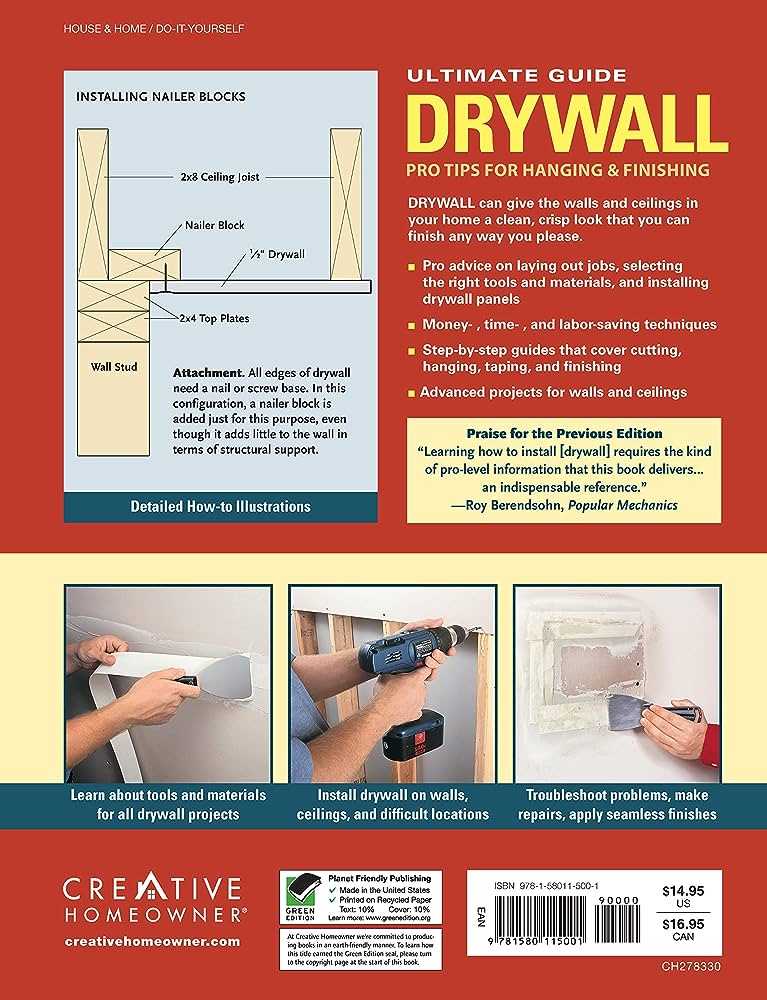

Installing sheetrock, also known as drywall, is a crucial step in building construction. This material is made of gypsum plaster pressed between two thick sheets of paper. It is widely used in the construction industry for its ease of installation and versatility.

Before installing drywall, it is important to prepare the wall surface. This includes removing any old plaster or paint, ensuring that the surface is clean and smooth. Any imperfections should be repaired before proceeding with the installation.

Once the wall surface is ready, the drywall sheets can be installed. The sheets are typically 4 feet wide and come in various lengths, allowing for flexibility in installation. They can be attached to the wall using screws or nails.

Prior to attaching the drywall sheets, it is important to measure and cut them to the appropriate size. This can be done using a utility knife or a specialized drywall cutting tool. Care should be taken to ensure accurate measurements and clean cuts.

When installing drywall, it is important to start from the top and work your way down. This helps to ensure that the sheets are properly aligned and fit together seamlessly. Each sheet should be secured to the wall using screws or nails, placed approximately every 12 inches along the edges and every 16 inches in the center.

Once the drywall sheets are installed, the seams between them need to be covered with joint compound or drywall tape. This helps to create a smooth and seamless surface. The joint compound should be applied using a trowel, and multiple coats may be required to achieve the desired finish.

After the joint compound has dried, the drywall can be sanded to create an even surface. This helps to remove any imperfections and prepare the wall for painting or other finishing touches.

In summary, the installation of drywall is an important step in the construction process. Proper preparation of the wall surface, accurate measurement and cutting of the drywall sheets, and careful installation techniques all contribute to a successful installation. With the right tools and techniques, drywall can be installed quickly and efficiently, providing a sturdy and attractive finish to any wall.

Preparing the Surface

Before starting the installation of drywall, it is important to properly prepare the surface. This is a crucial step in the construction or building process, as it ensures a smooth and even finish for the drywall.

The first step in preparing the surface is to remove any existing wall coverings, such as wallpaper or paint. This can be done using a scraper or a chemical wallpaper remover. It is important to remove all traces of the previous wall covering to ensure that the drywall adheres properly.

Once the wall is free from any coverings, it is important to inspect the surface for any damage or imperfections. Any holes, cracks, or dents should be repaired before installing the drywall. This can be done by applying a joint compound or plaster to fill in the damaged areas and then sanding it down to create a smooth surface.

After the surface has been repaired, it is important to clean it thoroughly. This can be done by wiping down the walls with a damp cloth to remove any dust or debris. It is important to ensure that the surface is clean and free from any particles that could interfere with the adhesion of the drywall.

Once the surface is clean and dry, it is important to apply a primer. This helps to seal the surface and create a better bond between the drywall and the wall. The primer should be applied evenly using a paint roller or brush, and allowed to dry completely before proceeding with the installation of the drywall.

In addition to these steps, it is also important to measure and mark the wall to determine the layout of the drywall. This can be done using a tape measure and a pencil. It is important to accurately measure the wall to ensure that the drywall fits properly and there are no gaps or overlaps.

Overall, preparing the surface is an important step in the installation of drywall. By properly repairing, cleaning, and priming the surface, you can ensure a smooth and even finish for your drywall installation. This will result in a professional-looking wall that is ready for further finishing, such as painting or wallpapering.

Cleaning and Repairing

When it comes to construction and building materials, drywall is a popular choice for partitions and walls. Also known as sheetrock or gypsum board, drywall is a versatile material that is used in residential and commercial buildings.

Over time, drywall can get dirty or damaged. It’s important to clean and repair drywall to maintain its appearance and functionality. Here are some tips for cleaning and repairing drywall:

- Cleaning: To clean drywall, start by removing any dust or debris using a dry cloth or vacuum cleaner with a brush attachment. For more stubborn stains, you can use a mild detergent mixed with water. Gently scrub the stained area with a sponge or soft brush, being careful not to damage the drywall surface. Rinse the area with clean water and allow it to dry completely before painting or applying any finishing touches.

- Repairing small holes: Small holes in drywall can be easily repaired using a patching compound. First, clean the area around the hole and remove any loose debris. Apply the patching compound to the hole using a putty knife, making sure to smooth it out evenly. Allow the compound to dry according to the manufacturer’s instructions, and then sand it down until it is smooth and flush with the surrounding wall. Finally, prime and paint the patched area to match the rest of the wall.

- Repairing larger holes: For larger holes in drywall, you may need to use a patch kit or replace the damaged section entirely. If using a patch kit, follow the manufacturer’s instructions to cut a patch that fits the size of the hole. Apply the patch to the hole using a patching compound, and smooth it out with a putty knife. Once the compound is dry, sand it down and finish with primer and paint. If replacing the damaged section, cut out the damaged area and install a new piece of drywall. Secure the new piece with screws or nails, and then finish with joint compound, sanding, and painting.

By regularly cleaning and repairing drywall, you can ensure that your walls and partitions remain in good condition and maintain their aesthetic appeal. Remember to always follow safety precautions and consult a professional if you are unsure about any repairs.

Priming

Priming is an essential step in the process of finishing drywall. It involves applying a coat of primer to the gypsum board before painting or applying any other type of finish. Priming helps to seal the surface of the drywall, providing a smooth and even base for the final finish.

Priming is important for several reasons. First, it helps to prevent the gypsum board from absorbing moisture from the paint or other finishing materials, which can cause the drywall to warp or crack. Additionally, priming helps to improve the adhesion of the paint or finish, ensuring that it adheres properly to the surface of the drywall.

There are several types of primer that can be used for priming drywall. One common option is a latex-based primer, which is easy to apply and dries quickly. Another option is an oil-based primer, which provides a more durable and stain-blocking finish. It’s important to choose a primer that is compatible with the type of paint or finish that will be applied to the drywall.

Before priming the drywall, it’s important to prepare the surface properly. This involves sanding any rough areas or imperfections, as well as cleaning the surface to remove any dust or debris. Once the surface is clean and smooth, the primer can be applied using a brush or roller.

When applying the primer, it’s important to work in small sections and apply a thin, even coat. This will help to ensure that the primer dries properly and provides an even base for the final finish. After the primer has dried, the surface can be sanded lightly to remove any imperfections before applying the final finish.

Overall, priming is an important step in the process of finishing drywall. It helps to seal the surface of the gypsum board, improve the adhesion of the paint or finish, and provide a smooth and even base for the final finish. By taking the time to properly prime the drywall, you can ensure a professional and long-lasting result.

Measuring and Cutting

When it comes to installing drywall partitions in a building, accurate measurements and precise cutting are essential. The process of measuring and cutting drywall, also known as sheetrock, is a crucial step in the construction of walls made from gypsum plaster.

To begin, gather all the necessary tools for measuring and cutting drywall. These tools typically include a tape measure, a utility knife, a T-square or straightedge, and a pencil. Having these tools on hand will ensure that the process goes smoothly and efficiently.

Start by measuring the dimensions of the wall where the drywall will be installed. Use a tape measure to measure the height and width of the wall, taking into account any openings for windows or doors. It’s important to measure accurately to avoid any unnecessary waste or gaps in the installation.

Once the measurements have been taken, transfer them onto the drywall sheet using a pencil and a straightedge or T-square. Mark the dimensions clearly on the drywall, ensuring that all sides are labeled correctly.

Next, it’s time to cut the drywall to the appropriate size. Lay the drywall sheet on a flat surface, making sure it is secure and stable. Use a utility knife to score the drywall along the marked lines, cutting through the top layer of paper and into the gypsum core.

After scoring the drywall, gently bend the sheet along the score line to break it along the cut. Use the utility knife to cut through the remaining paper layer on the back side of the drywall. This will ensure a clean and precise cut.

Repeat the measuring and cutting process for each piece of drywall needed for the wall. It’s important to cut each piece accurately to ensure a tight fit and a professional-looking installation.

Once all the drywall sheets have been cut to size, they can be installed on the wall using screws or nails. It’s important to follow the manufacturer’s instructions for installation and to leave appropriate gaps for expansion and contraction.

In conclusion, measuring and cutting drywall is a crucial step in the construction of walls. By taking accurate measurements and making precise cuts, you can ensure a seamless installation and a finished wall that is both functional and aesthetically pleasing.

Accurate Measurements

Accurate measurements are crucial in drywall construction. Whether you are installing a partition or building a wall, precise measurements ensure that the drywall material fits perfectly and provides a smooth finish.

Before you start measuring, it is important to gather all the necessary tools, including a tape measure, pencil, and level. These tools will help you achieve accurate measurements and ensure that the drywall is cut to the correct size.

When measuring for drywall, it is essential to consider the thickness of the material. Drywall typically comes in different thicknesses, such as 1/2 inch and 5/8 inch. Measure the thickness of the existing walls or consult the building plans to determine the appropriate thickness for your project.

Start by measuring the height of the wall from floor to ceiling. Use the tape measure to get an accurate measurement, and mark the measurement with a pencil. Repeat this process for each wall that needs drywall installation.

Next, measure the width of the wall from one end to the other. Again, use the tape measure to get an accurate measurement and mark it with a pencil. If the wall has any openings, such as windows or doors, measure the width of these openings separately.

Once you have measured the height and width of the walls, it is time to calculate the quantity of drywall material you will need. To do this, multiply the height and width measurements together. For example, if the height of the wall is 8 feet and the width is 12 feet, the total square footage is 96 square feet.

It is important to account for any additional cuts or waste when calculating the quantity of drywall material needed. It is recommended to add 10-20% to the total square footage to account for these factors.

Accurate measurements are essential for a successful drywall installation. Take your time when measuring and double-check your measurements to ensure that the drywall fits properly and provides a solid foundation for your walls.

Video:Everything You Need to Know About 14 Drywall A Comprehensive Guide

Hello, I am Beverly J. Sanders, the voice behind the diverse articles you come across on styves.co.za. My passion lies in exploring the nuances of home improvement and sharing tips that can help you transform your living space into a haven of comfort and style. From the latest trends in home decor to practical cleaning advice, I cover a broad spectrum of topics to cater to a wide variety of interests.

In my recent works, I have delved into the advantages of incorporating a horizontal Murphy bed into your home to save space without compromising on design and functionality. I also explored the benefits of having a free-standing electric fireplace that not only adds warmth to your home but also brings a sleek and modern design to any living space. My articles are a rich resource, offering insights into different products and home improvement strategies that can enhance the quality of your life.

I believe in the power of details; a belief that reflects in my comprehensive guides where I discuss even the overlooked aspects of home decor, such as the impact of baseboard trim in enhancing the overall look and feel of your home. I am constantly on the lookout for innovative solutions and products that can add value to your home and life.

Join me in my exploration as I continue to bring you the latest trends, tips, and insights in the home improvement world. Let’s create a home that is not just a place to live, but a reflection of style and personality.